|

Students, Facilities and Projects

(see

our virtual

tour for more detail) |

| |

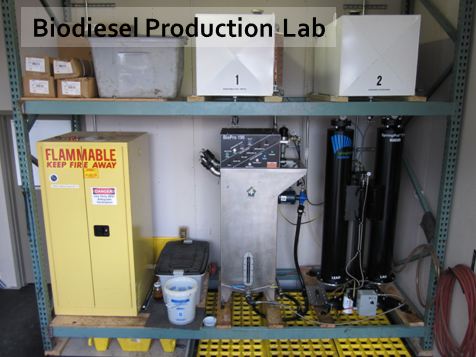

Our batch biodiesel processor and dry-wash

system (by

Springboard Biodiesel) is used to convert used fryer oil

from campus dining halls to quality biofuel, which is used for

greenhouse heating and powering tractors at the

MSC

Equine Rehab Center. |

Shawn and Rob are preparing a titration of biodiesel

to determine residual soap and catalyst levels. |

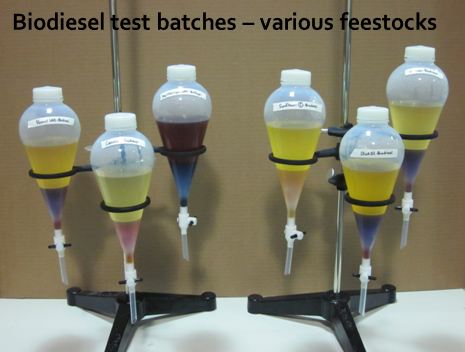

Test batches of biodiesel using various

feedstocks, including vegetable oils and animal fats. The

separation line is glycerol, which settles to the bottom of the

funnel. |

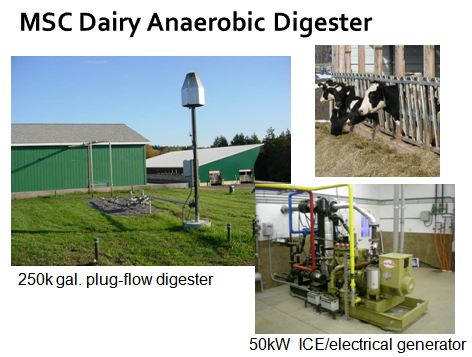

The

College's dairy farm produces about

900 kWh of electricity each day day (that's the equivalent of an typical home's

monhtly energy use) from cow maure. Bacteria in the

digester

break down the organic wastes into organic acids which are

broken down further by methanogenic bacteria that produce

methane gas. The "biogas" is about 60% methane and 40% carbon

dioxide. |

Students touring the Madison County

Landfill biogas combined heat and power facility. |

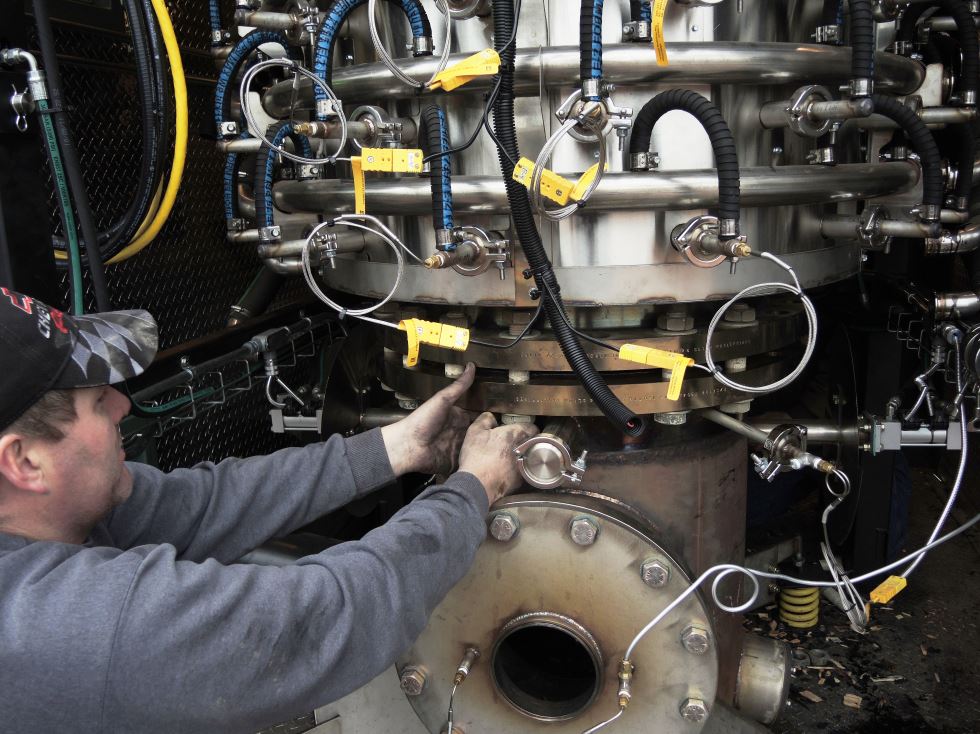

Morrisville technician servicing the

BioMax100 gasifier. This unit

generates heat and electricity for

Commons I (student housing). Biomass (wood chips) is

converted to syngas in the gasifier, which is filtered and then

combusted in two GM Vortec engines connected to generators

producing a net 100 kW electric output. |

Students preparing the wood gasification

Power Pallet for a

live demonstration (electricity from wood chips

and horse manure!). This unit has

been customized by MSC students. See how it works:

here! |

Students are changing the screens on the

wood chipper/grinder used to process cull logs (and other

biomass residues, see below) from campus

properties for use as biofuel. |

Students are processing horse manure and soiled bedding to

evaluate the material as a potential bioenergy feedstock. |

Dr. Hofmeyer tightens tower bolts on a

very cold installation at a wind turbine test site in Tully, NY. |

Ryan and Tyler practice fusing HDPE pipe,

which is commonly used as penstock material for microhydro

electric systems. |

Renewable Energy students install

the intake for a

microhydro system at

Oxbow Falls County Park. |

Dr. Hofmeyer getting his feet wet!

Oxbow

Falls County Park

micro hydro installation. |

Tim and Josh mount a micro hydroelectric turbine

during lab at the

Galbreath Farm. |

Dr. Ballard and Tyler are checking the

Bergey Excel 10kW wind turbine (@120 ft.) to determine what is needed to

repair the furling cable (note the tail is not in its furled

position, as it normally would be when technicians climb the

tower). |

As part of their solar PV lab, Renewable

Energy students work with a local installer on this

Solarize Madison

job. |

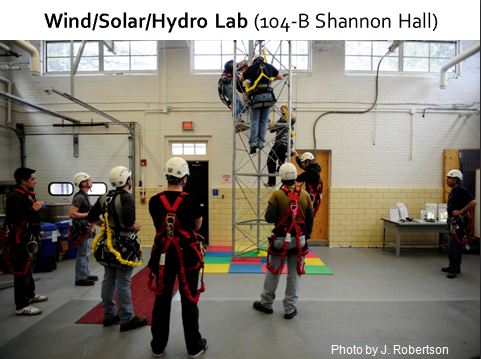

Tower climbing and rescue class starts out

on the 17-ft. indoor tower in the Shannon Hall classroom...later

in the semester students work outside on the 120-ft. tall Bergey

tower! |

The Shannon Hall wind/solar lab gives students hands-on

experience with the electrical components for both wind and

solar PV systems. |

| |

| MSC Controlled

Environmental Agriculture (CEA) Greenhouse -

Aquaponics Facility

(for more info. contact:

Eric Bremiller) |

Floating raft pond system. Lettuce is

grown in rock wool plugs held in place in foam boards. The roots

are submerged in the pond (aeration stones provide air to the

roots). |

Crop diversification on the raft system.

The raft system is connected to the tilapia tanks. The fish

provide fertilizer (dissolved nutrients; fish waste solids are

removed prior to the pond, and water is UV sterilized), and the

plants help "clean" nutrients out of the water. |

NFT (nutrient film technique) using

"gutters" to deliver a constant stream of nutrient-rich water to

the plant roots. Water is recirculated from a sump tank to the

gutters and monitored daily for nutrient an pH levels. |

Ag. business students, Dr. Xu Pei, and

Eric Bremiller (greenhouse manager) harvesting lettuce to be

sold by Morrisville Fresh. Much of our lettuce is used

at the dining halls on campus, as well as the

Copper Turret

restaurant, which is operated by Morrisville

Auxiliary Corporation (MAC). |

Scrubbing the fish tanks is a regular

occurrence, trying to keep up with the algae. |

One of our tilapia, ready for harvest. Our

fish are sold live to an Asian market in Syracuse. |

| |

|